Products

Pressure housings: Manufacturing

Pressure housings: Simple in concept and nuanced with details.

Downhole pressure housings are simple in concept but nuanced in their details. The simple part is that a pressure housing is tube that protects the internal components (payload) from two things: the external fluid's crushing force and keeps the payload dry.

The nuanced parts are the details related to:

Material Properties:

- strength vs. brittleness

- corrosion resistance

- magnetism

- gamma ray attenuation

- galling tendency

- cost

- machinability

- commercial availability

Feature Designs:

- straightness

- concentricity between the ID/OD

- concentricity between other diameter features seal design and manufacturing tolerances

- thread design and manufacturing tolerances

- connector orientation features

- internal payload latching designs and manufacturing

- multi piece welded design vs. single piece design

- axial hydrostatic end loading

- radial fluid ports

- radial latching features for external centralizers

- rotational orientation tolerances between end features

- testing requirements

At industry's disposal are our decades of experience helping engineers design pressure housings and decades of experience making pressure housings.

Synonyms for Pressure Housings

Pressure barrel, Instrument Barrel, Pressure vessel, Sonde housing

Function of Pressure Housings

A down hole pressure housing is a precision tube of high strength material with sealed ends that houses and protects downhole instruments from wellbore fluid and external hydrostatic forces.

Critical manufacturing components

Concentricity between ID/OD (uniformity of wall thickness), Precision of ID and OD size and shape, Straightness, Precision of machined end closures, Welding, Material properties, Pressure testing

Materials

Common materials are 17-4 stainless, Nitronic 50, Inconel 718, Copper Beryllium, Copper Nickel and Titanium Alloys.

Tube source

Most pressure housings are made from bar material that is deephole drilled to produce a precision tube. Mill produced tubing requires large volume minimum orders and consequently has high initial costs. National K Works specializes in economically producing precision tubes from exotic metals. Typical OD sizes range from 0.75" (19mm) for slim hole production logging tools to 5.0" (127mm) for ultra-high pressure deep water open hole logging tools. Lengths have ranged from 6" (152mm) to 216" (5.5m). Longer lengths are easily manufactured.

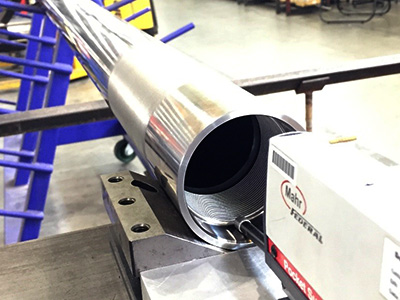

Concentricity

Concentricity (uniformity of wall thickness) is one of the most critical yet under toleranced features of a pressure housing. National K Works specializes in producing tight concentricity tolerances between the ID and OD. Our standard tolerance is 0.010" (0.25mm) maximum positional tolerance between the ID and OD (+/-0.005" (0.13mm) maximum wall thickness tolerance) along the entire length of the pressure housing.

Machining

National K Works specializes in machining precision threads, blunt starts on threads, critical seal bores, fluid porting (radial and axial) features, internal cavity features for latching and orienting chassis and connectors, internal and external tool joint orientation features, external identification bands for depth correlation of sensors, deep bore internal chambers for seal ramps and connector guidance.

Welding

Welding is performed on National K Works' proprietary welding machines that have program controlled variables pulled from a library of welding procedures. Joints are not welded by hand. Weld joint integrity is verified during pressure testing. Thin cross section welds like those found on internal gas chambers are verified with Helium leak testing.

Straightness

Housings are straightened prior to machining end features to ensure perpendicularity to centerline. Critical fits between chassis and bore are verified with a functional "drift" specimen that replicates the chassis and its fit to the pressure housing.

Positional tolerances

When critical multi-bore sealing configurations are inaccessible with conventional measuring tools (such as those on formation testers), National K Works verifies the position of the bores using National K Works designed gage fixtures that replicate the actual functions of the mating parts.

Pressure Testing for Downhole Pressure Housings

Pressure testing verifies the mechanical integrity of the pressure housing and the seal integrity of all the connections on a pressure housing. It is a crucial risk management test to avoid failures in an actual well. National K Works pressure tests to 35,000 psi (241MPa) maximum at ambient temperature. We have made, and have in inventory, seal testing fixtures for over 400 different tool joints used across the industry.

Contact Us for Pressure Housing Manufacturing and Testing

If you are looking for an expert and precision company to manufacture and test pressure housings, don't hesitate to contact us today to ask any questions you may have or discuss the details of your pressure housing manufacturing and testing needs.